The Breda Argus, An Innovative Shotgun With Roots In the Browning Auto-5

- Rus Hinkle

- Jul 18, 2024

- 5 min read

In first half of the 20th century, the Ernesto Breda Italian Society, more commonly known simply as Breda, established itself as one of Italy’s largest manufacturing conglomerates. Breda’s primary portfolio was focused on mass transport, and included busses, trolly cars, and locomotives. During the Great War, Breda was subcontracted to produce various small arms components for the Royal Italian Army. Breda’s firearms division would remain mostly dormant during the 1920s, with Breda shifting its focus to the now burgeoning aircraft market. Breda’s aeronautical ventures are a wide story of their own, but we will litigate these some other time. By the 1930s, Breda’s firearms division was called back into service to produce machineguns for the Royal Italian Army, along with an impressive burst-fire rifle for Costa Rica that predated John Garand’s autoloader. In this series of articles, we will be discussing the mechanics and lineage of various Breda firearms. Today, we will be starting with the Argus.

The Breda Argus traces its lineage back to the original John Browning Auto-5. The Auto-5 was the first semiautomatic shotgun introduced on to the market circa 1900, and was produced across the globe virtually unchanged for nearly a century. The Auto-5 was not without its faults. Primarily, it is an absolute nightmare to dissemble for maintenance, and its construction is not intuitive for the average user to understand the specific disassembly sequence.

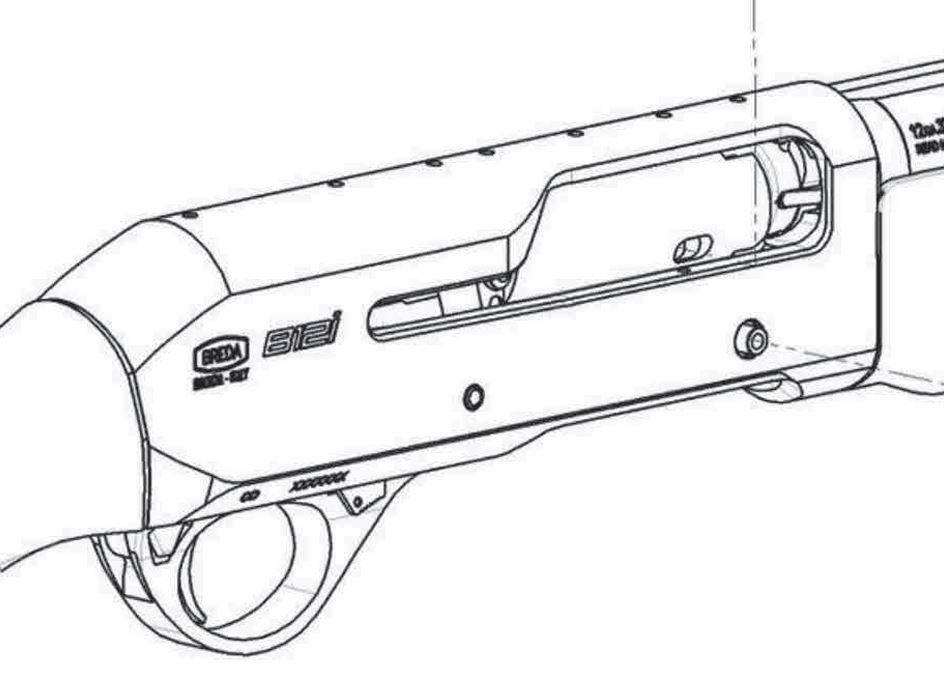

In 1947, Breda introduced their version of the Auto-5, the model 1001. This fork of the Auto-5 features tooless disassembly, a reversible safety for left-handed shooters, a unique stock system that is fully adjustable for drop and cast, and a 2-piece receiver design that would be seen again later on the Benelli 121. Our Argus today is a further refinement of the 1001, and carries over all but the adjustable stock feature from the previous 1001. This specific Argus example was produced in 1976.

When removing the forends, we can clearly see the direct lineage from the Auto-5 at play. The Argus, like the Auto-5, is a long-recoil operated firearm. This system utilizes the recoil generated directly from the shell and uses it to cycle the action. The bolt group, being locked into the barrel, recoils rearward with the barrel to dampen the recoil imparted into the user’s shoulder. Once the connected action reaches its rearmost travel, the bolt trips a sear and is disconnected from the barrel. The barrel returns forward from the barrel spring under the forend, ejecting the spent cartridge. Once the barrel returns to its ready position, a second sear is tripped, and the bolt flies forward, loading another shell from the magazine tube and readying the gun to fire again.

In order to allow the firearm to reliably cycle the menagerie of loads on the market, the Auto-5 utilizes a series of friction rings that apply braking pressure to the barrel when cycling. There are primarily two modes of operation; a setup for light loads, and a setup for heavy loads. Failure to use the correct setup for the desired loads can result in short-stroke, or permanent damage to the firearm.

The Auto-5 uses only two friction rings; a steel and a brass ring. The Argus further introduces a third item- a washer. This washer sits between the barrel spring and the steel friction ring. Normally, on an Auto-5, the “light load” setting is to have the steel ring snug against the receiver behind the spring, and the “heavy load” with it in front of the spring, cupping the brass ring. On the Argus, one simply needs to flip the steel ring toward or away from the brass ring to change from light to heavy loads.

The Argus's barrel extension is noticeably slimmer than the Auto-5’s, with much unnecessary extra material behind the locking surface being deleted. The Argus's barrel and barrel ring are also milled from a single piece of steel. This leads to a much higher quality barrel at the cost of longer machine time. The astute of you will also note that the Argus sports an ejector reminiscent of the later-pattern Auto-5s sporting two claws.

More weight savings measures have also been introduced into the receiver. The Auto-5’s receiver has much thicker walls versus the Argus. The aforementioned two-piece receiver also plays a role here. The Argus’s “upper receiver”, or “top cover” is simply a piece of sheet steel covering the action. The barrel is entirely retained within its extension recesses in the receiver and along the magazine tube. Like a Kalashnikov, the existence of the top cover is entirely unnecessary to the function of the firearm, and is merely there to prevent foreign objects entering the action and to prevent blowback into the user’s face. Unpictured, the Argus's buffer tube is also threaded into the rear of the receiver. This greatly saves on materials compared to the Auto-5's vestigial buffer and stock tube milled directly into the receiver.

The largest advantage that the Argus brings to the table is arguably its ease of disassembly. As previously mentioned, the Argus sports toolless disassembly: all major component groups can be removed from the receiver without a single tool. This process, does, however, follow and order of operations.

First, we rotate the safety into the “safe” position. Applying some pressure from the opposite end, and with enough wiggling, the safety lever pops out from its holes in the receiver. The safety also acts as the crosspin for the trigger, which now can be simply pulled out from the bottom. Next, we unscrew the forend cap and remove the forend and barrel, which just slide off the magazine tube. Lastly, depress the shell stop on the bottom of the bolt group, and it slides out the front of the receiver. The recoil spring is captive inside the buffer tube in the stock (a feature we will see standardized in later models), and can be removed for maintenance via a large flathead bolt in the back of the stock under the buttpad. The remaining component groups can be further disassembled with punches, screwdrivers, and picks.

For those of you that have fully taken down an Auto-5, I will not relitigate the process here. Suffice to say, comparatively the Argus is a breeze. I have fully-stripped countless of “granddaddy's old” Auto-5 and their various clones over the years and dread the process each time, even with my own Savage 720. While, the Auto-5 is not in my top-5 worst guns to work on, it is definitely an honorable mention simply for the sheer tediousness of disassembly. I have to forgive the Auto-5 for being as it is, however; this is generation-1 technology, and it is very seldom that gen-1 gets it right the first time. It was only sixteen years prior that Hiram Maxim invented the machine gun, and it would take another seventeen years for the first nation to finally adopt a semiautomatic service rifle.

The Breda line of long-recoil shotguns are quite rare here in the United States, and have many models and names, most of which are unfortunately only mentioned in the Breda catalogs. The firearms themselves are very scant on details. If you have one, please let us know in the comments below.

Rus Hinkle

Lead Gunsmith, Banshee Brands

Comments